DRONCO

BECAUSE EXPERTS SET THE STANDARDS

With an experience of 40 years, the German DRONCO company is one of the biggest companies, manufacturer of abrasive disks, cutting disks, abrasion and polishing, diamond cutting disks, ceramic abrasives from Europe, and their products are being sold in over 100 countries.

Using state-of-the-art technology and highly-qualified employees, every day are produced approximately 200.000 cutting and polishing disks, 400.000 laminate disks, 6.500 diamond disks from steel of high quality.

Ever since 1998 the company was oriented towards research and innovation receiving numerous prizes for resourcefulness in the abrasive industry, we remind at least the one in 2001 awarded by Fraunhofer Society, the Research and Innovation Institute which reunites 59 such organizations in Germany.

At the same time DRONCO is the first company in the world having launched the “FREECUT” cutting disk (reduces the attrition of the disk while cutting by pilling the material), the extra thin disk or the laser welding of the diamond disks.

Due to the innovation and research department the company DRONCO launches on the market at an interval of 90 days a new product.

The collaboration DRONCO-ROCAST NORD is a very recent one (begun in the fall of 2010) and completes our range of suppliers of superior quality products which we can offer at an accessible and competitive price, especially due to the tradition, experience and efficiency our partners show but also due to the new strategy which ROCAST NORD applies regarding the effectiveness of our own processes and operations.

Our slogan when we promote the superior quality brands from the ROCAST NORD portfolio is:

“If you want to obtain quality results you have to use quality tools”

Among the traded products we enumerate the range of stainless steel cutting disks, grinding disks, the range of segmented and continuous diamond disks etc.

The products are set in a hierarchy on three distinct lines: Perfect, Special and Evolution, a short description as follows:

PERFECT: universal, appropriate for regular materials of general usage, works with diverse application, domestic or industrial, of good quality, the best sold range at a reasonable price.

SPECIAL: special line for handicraft or industrial users, conceived in order to be used exclusively for the category they were designed for.

EVOLUTION: in this range there are products with the most innovation, using materials of superior quality, they are economical for using in the industrial regime, designed especially for professional works, it combines attributes such as the life span and the increased working speed and maximum operating safety.

We describe bellow some of the classifications and proprieties of the DRONCO products:

DRONCO EXPRESS – under this name we find all the products characterized by extra-thin thickness of the best quality. It assures a speed supplement, much faster while cutting due to the thickness, clean cut without rims, less wasted material consequent to the cut, more comfort through a minimum effort at the same cutting pressure, of reducing the noise, the vibrations and the quantity of dust resulted from the cutting process. BIA approved (the BG Institute for Safety), in conformity with OSA – tested for safety, Made in Germany.

DRONCO PROTECT - innovative products which protect the users through special characteristics reducing the disturbing, harmful factors, offering a less noisy working process, with fewer vibrations and less dust.

DRONCO FREECUT – through the conic shape of the cutting disk in transversal section of 2 mm at the exterior and 1 mm at the interior optimizes the cutting performance conferring more safety and precision in long cutting, avoiding the dangerous”kick-back” (throwing back the grinder effect) stops the disk blockage, increases the cutting speed by reducing the attrition of the disk on the inside in the case of cutting thicker material.

DRONCO CUT+GRIND – in conformity with the new tendencies in simplifying the working processes, the new brand combines two characteristics: cutting and rectifying in a single operation without changing the disk.

Of a superior quality it is employed both for steel and for stainless steel.

DRONCO SPECIAL MULTI – a new special disk which permits cutting the different materials as structure (steel, stainless steel or stone) without being necessary to change the disk, with a thickness of 1, 2 mm which assure an easy and precise cut without special effort. Recommended for renovation works.

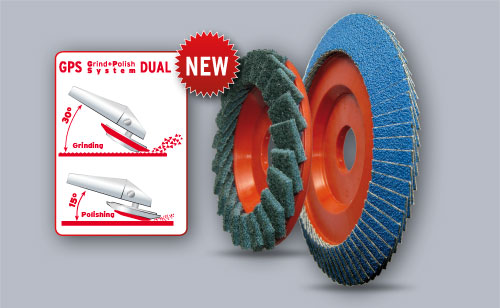

DRONCO INNOVATION - GPS DUAL Grind and Polish system

Fine, rough grinding and polishing with the same abrasive tool:

With the Dronco Grind and Polish System GPS Dual now makes this possible.The system consists of a 125 mm Flap disc and inserted into this is a 90mm flap disc with a different grain. Both discs are mounted together on the angle grinder. The change between rough and fine grinding is controlled by the pitch angle of the grinder: 30 % angle: rough grinding, 15 % angle: fine grinding.

DRONCO is a member of OSA (The Organization for the Safety of Abrasives). OSA was created in 2000 by 17 European companies renowned for establishing the safety standards regarding the abrasive products. Currently OSA has 49 members in the whole world; the abrasive products supplied by them are the safest form the point of view of labor safety. The only purpose of this organization is to assure the quality which remains constantly very high, in the interest of the users OF abrasive products. More information about OSA can be found on their official site by clicking HERE.

The system of quality management of the DRONCO products guarantees the high quality standards, the safety in operation certified in conformity with DIN EN ISO 9001:2008.

EN 12413 – safety standard for cutting and polishing disks.

EN 13743 – safety standard for abrasives

EN 13236 – safety standard for diamond disks

You can access the official site of the DRONCO company by clicking HERE.

For product information and offers from Rocast Nord, you can subscribe to the newsletter from our store, www.SuruburiOnline.ro